- #MASTERCAM 2019 CONTOUR FINISH CUT FEED OVERRIDE PRO#

- #MASTERCAM 2019 CONTOUR FINISH CUT FEED OVERRIDE SOFTWARE#

- #MASTERCAM 2019 CONTOUR FINISH CUT FEED OVERRIDE SERIES#

And, VERICUT offers the best tools available for analyzing, inspecting, and using the in-process, as-cut model.ĬNC Machine Simulation and Part VericationReduce crashes and close calls Eliminate on-machine prove-outs Reduce machine implementation time Create perfect rst-time parts Reduce scrap and rework

#MASTERCAM 2019 CONTOUR FINISH CUT FEED OVERRIDE SOFTWARE#

Plan your month at Machine Simulation Cutting Speed Optimization Program Verication Inspection & AnalysisĪ crash in VERICUTs virtual machining world can save you in the real one!VERICUT CNC simulation software enables you to machine parts on the computer before actual cutting occurs so you can eliminate errors that could ruin the part, damage the xture, break the cutting tool, or crash the machine! VERICUT also optimizes the cutting process so in addition to being error-free, your programs are fast and efcient. Attend a SOLIDWORKS 2019 event, enter our rendering contest, and learn about some cool tips and tricks at the daily online events.

#MASTERCAM 2019 CONTOUR FINISH CUT FEED OVERRIDE SERIES#

We’ve created a month-long series of events and activities around design innovation especially for our customers. All these articles will be stored in the category of “ SOLIDWORKS What’s New.”įield Technical Services Manager & CAM Team ManagerĬATI is declaring October Design Innovation MONTH. I hope this part of the What’s New series gives you a better understanding of the new features and functions of SOLIDWORKS 2019. Please check back to the CATI Blog as the CATI Application Engineers will continue to break down many of the new items in SOLIDWORKS 2019. This will be very beneficial when machining longer parts. This method will reduce the amount of repositioning time between cut which results in reduced cycle times and costs. VoluMill cut options now include a ZIG ZAG option which you can combine with Climb and Conventional milling when using VoluMill.

#MASTERCAM 2019 CONTOUR FINISH CUT FEED OVERRIDE PRO#

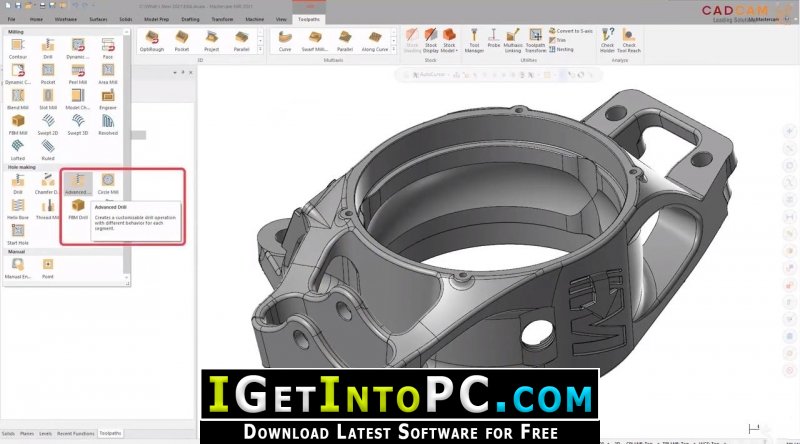

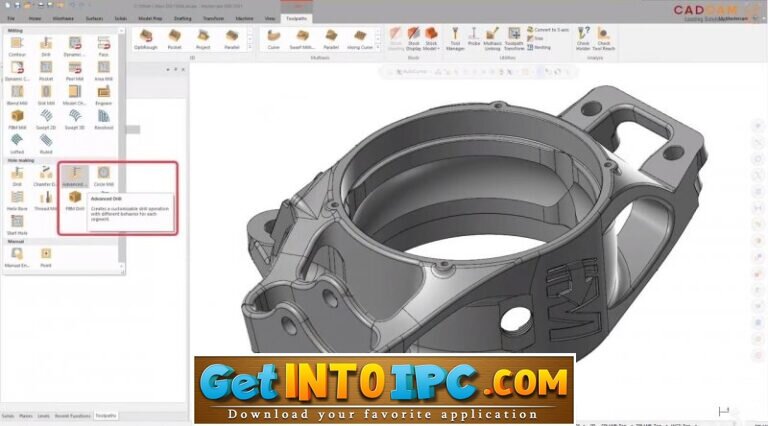

New ZIG ZAG option in VoluMill cut options in SOLIDWORKS CAM Pro It has an improved interface because it can now also be found in ‘Property Page’.ħ. Edit Toolpath has new and advanced capabilities in SOLIDWORKS CAM 2019. Which allows for more control and greater productivity.Ħ. In SOLIDWORKS CAM 2019, you can now modify the ‘Start/End Z Locations’ to be modified from holes created by Automatic Feature Recognitions (AFR). If programmers prefer to machine the holes first and the stock later. If it isn’t, the drill may crash into the stock. Start/End Z Locations to be modified from holes created by Automatic Feature Recognitions (AFR)ĪFR expects the stock above the hole to be machined, prior to rapid positioning in Z. This new option can be combined with Cutter Compensation to give ultimate control around edge breaking around a 3D curve.ĥ.

The Operation Parameters Contour Tab has a check box option for ‘Chamfer Machining’. When you select the Contour Operation of the curve feature. Ball end cutters are also supported.įor example, existing 3D Curve features can now be chamfer milled.

You can create additional chamfer operations with the Curve Feature. The software automatically recognizes chamfers. In the Mill Features tab, you can apply chamfers to curve features.

OR you can simply input your own numbers for the ‘Arc Feedrate Override’. You can control by modifying ‘System Calculated Feedrates’ OR In the past, the only way to control this functionality, was in the post processor.īut now we can control the Arc Feedrates in SOLIDWORKS CAM. By being able to control and slowdown these rates will help aid in longer cutter tool life. Arc feed rates are calculated based on the radii. To allow different feed rates for arcs, machining slows down when approaching sharp corners. For customers that run a mixture of different machines and want different machining strategies for each different machine. In the past, customers with machines such as, laser, plasma and/or water jet would create a separate technology database for each of these types of machines, since each machine usually required different default machining strategies. Now you can specify strategies for your laser, plasma, water jet or CNC machines. Now able to define specific default strategies based each machine. Assign Default Strategies to Machine Types Which allow for greater accuracy for simulating stock removal when using Taper and Neck style of tools.Ģ. We now have Taper and Neck options for the Non-cutting portion of the tool. Now we can properly define the Operations Parameter Dialogue Box in the Tech DB. In the past, our inability to define the detail of the tool shank did not show accurate machining simulation. Taper and Neck options for non-cutting portion of the tools SOLIDWORKS 2019 has some great enhancements in SOLIDWORKS CAM. Listed below are seven updates and improvements to CAM functionality within SOLIDWORKS.ġ.

0 kommentar(er)

0 kommentar(er)